Over the last 30 years there have been various ways of capturing an impression of the feet for making insoles and orthotics.

From foot wax impressions, foam boxes to slipper casting in plaster and plaster sock casting. All have their benefits and drawbacks. I have to say that I have always been a fan of slipper casting in plaster as it is a very accurate technique.

The advantages of this technique is that it can produce a neutral or a semi pronated cast, which basically means capturing the foot in the corrected position rather than the position that it is already in. But of course it is not without it’s drawbacks. It is messy dipping plaster bandage in water then holding the foot in the required position and the casts have to dry a bit before they are sent to the laboratory. The technique requires a high degree of practitioner skill not only to get the cast off the foot but also to be accurate. The resulting casts are delicate and require careful handling and packing to prevent damage or distortion when they are posted to the orthotic laboratory for manufacture. Plaster sock casting is similar but as the name suggest comes up the foot further and is used when making appliances which come above the ankle or knee and has the same advantages and drawbacks.

Wax impressions have largely been superseded due to problems with accuracy but foam boxes are still popular, particularly here in Spain. One of the problems with these is that it is difficult to get the foot into the corrected position and all too often I hear that the pt was just made to stand normally in the foam box when the cast was taken therefore not capturing the ideal position for the foot. The advantage being that they are not messy.

As with most things in life, technology has moved forward and created a better alternative.

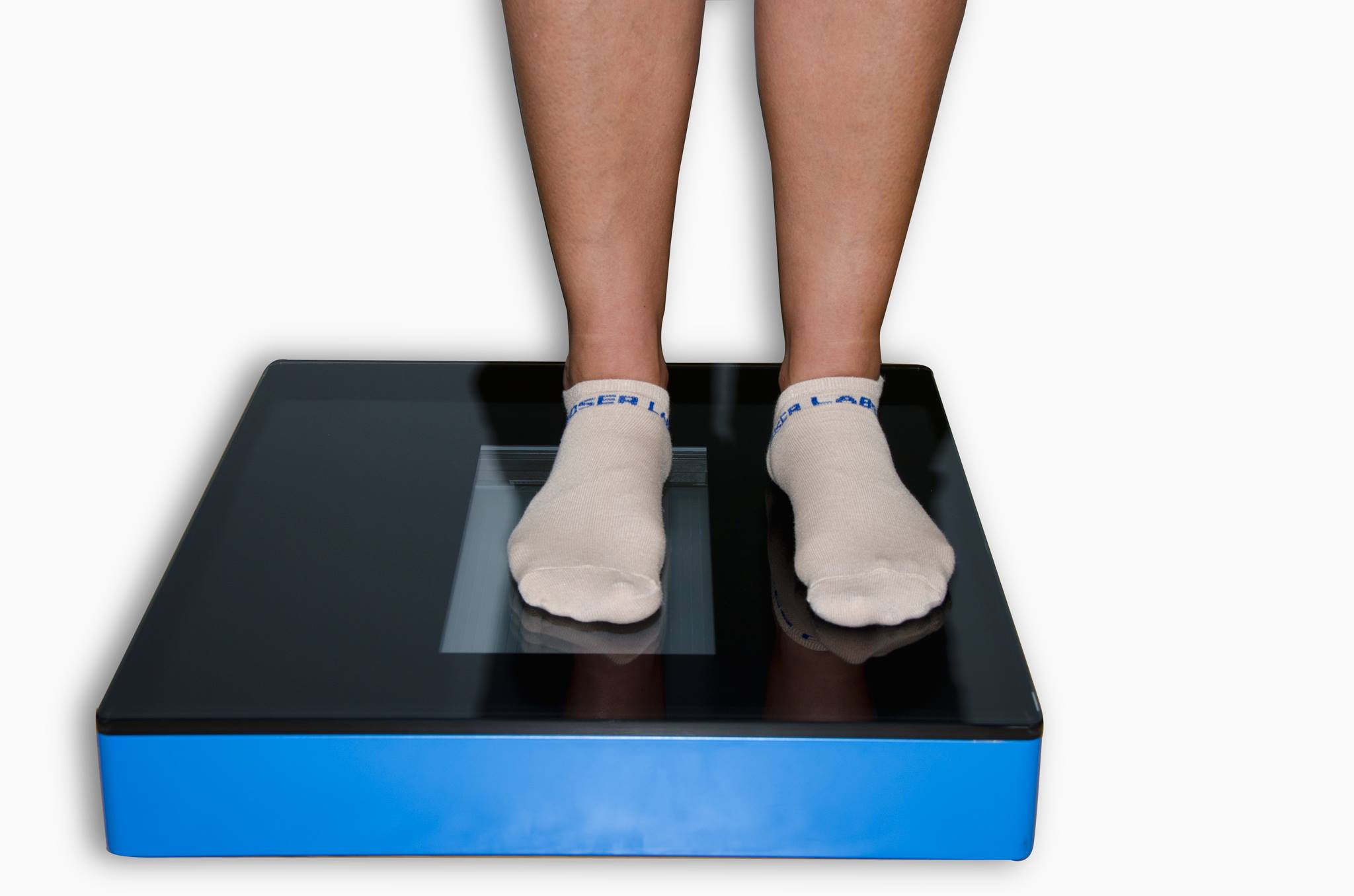

Over the last few years 3D laser scanning the foot has become an accurate way to capture a cast or 3D image of the foot. This can be done with the foot standing in the normal position giving great 3D images of the foot showing increased areas of pressure under the foot known as pressure mapping.This enablies better visualization and diagnosis of what is happening under the foot. The feet can also be captured in the corrected position and of course there is no messy plaster all over the clinic. The 3D image can be digitally sent instantly to the laboratory with the prescription or instructions if you like of, how the podiatrist want the orthotic or insole made. The whole procedure is speeded up by not having to pack and post delicate casts.

One of the problems of producing orthotics in Spain is that people wear sandals and flip flops of a large portion of the year. With this technology patients can buy specific sandals in shoe shops here and the insole or orthotic and be made to replace the existing insole in the sandal. Or can be used to make a flip flop with a custom foot bed.

Philip Mann Podiatrist/Chiropodist Tel 686912307 or www.footpodiatrist.com